RFID Technologies Adoption Across Industries: Data Demands Fuel Innovation - RFID technology is no longer confined to retail. From hospitals to hangars, production lines to distribution hubs, industries are turning to RFID for the same reason: the need for accurate, real-time visibility into assets, products, and processes.

Healthcare:

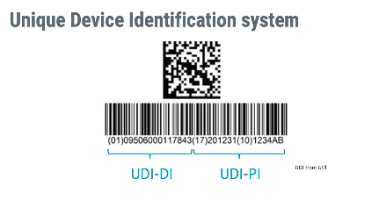

Patient safety and asset tracking: RFID Technologies enables accurate tracking of medical devices, pharmaceuticals, and even patient movements to reduce errors and improve compliance.

Inventory optimisation: Real-time data ensures that critical supplies are available where needed, minimising waste from expired stock.

Regulatory compliance: RFID supports stringent tracking and reporting requirements in healthcare.

Aviation:

Aircraft maintenance tracking: RFID tag labels on parts allow precise monitoring of component lifecycles and maintenance schedules.

Baggage handling: RFID-based baggage tracking dramatically reduces lost luggage rates while improving passenger satisfaction.

Regulatory inspections: Real-time data streamlines audits and compliance with aviation safety standards.

Supply Chain & Warehouse Distribution:

End-to-end visibility: RFID Technologies enables complete traceability from manufacturing through delivery.

Faster, more accurate fulfilment: Automation powered by RFID reduces manual scanning and speeds up goods movement.

Reduced shrinkage: Accurate real-time location data helps prevent loss or theft.

Manufacturing:

Work-in-progress tracking: RFID Technology identifies production bottlenecks and improves throughput.

Quality control: Real-time monitoring helps detect defects early, reducing scrap and rework.

Integration with Industry 4.0: RFID data feeds into IoT, robotics, and AI systems for predictive decision-making.

Automotive:

Component traceability: RFID Technologies ensures that every part can be tracked from supplier to assembly line to after-sales service.

Supply chain synchronisation: Just-in-time manufacturing depends on accurate, timely data — which RFID delivers.

Counterfeit prevention: Tagging key parts helps authenticate products and protect brand integrity.

Driving the Need for Innovation

As these industries adopt RFID, they face increasingly complex requirements:

RFID Label Tags that withstand extreme temperatures, sterilisation, and mechanical stress.

RFID Reader systems that work in challenging environments like metal-heavy factories or high-interference zones.

RFID Software Platforms that can integrate RFID data into AI-driven analytics for predictive insights.

This growing diversity of use cases is widening the field for RFID technology — demanding more advanced hardware, smarter software, and seamless integration with emerging technologies.